Products Center

Contact Us

Add:15-11, West District, China International Standard Parts Industrial City, Handan City, Hebei Province, China

Tel:+86-18634133666 +86-15284383180

E-mial:cindy@hdwxfasteners.com

WhatsApp: +86-15284383180

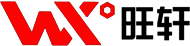

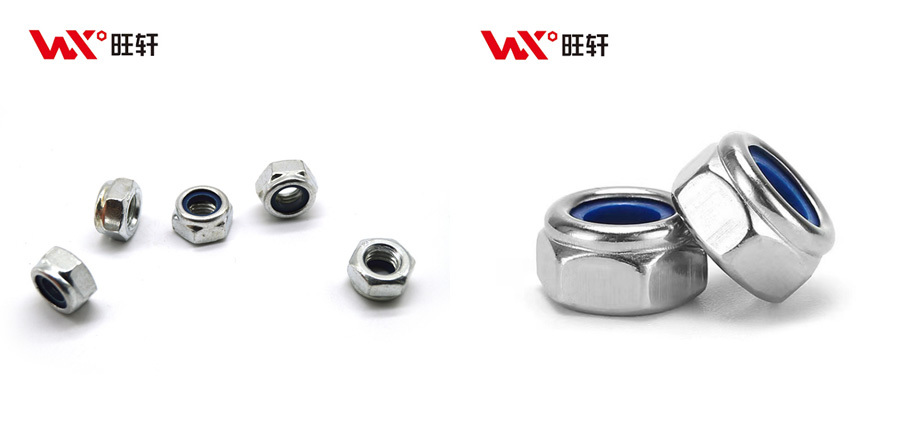

High Quality Galvanzied Nylon Insert Lock Nut

- Commodity name: High Quality Galvanzied Nylon Insert Lock Nut

- DESCRIPTION

-

Nylon lock nut /Lock nut

Name

Nylon lock nut /Lock nut Material Carbon steel/stainless steel

Grade 4.8 /6.8 /8.8 /10.9/ 12.9

Color White zinc/blue and white zinc/black/yellow zinc/natural color

Model number M6-M30/1/4"-1"

Packaging Bag put tray /box put tray /can be customized

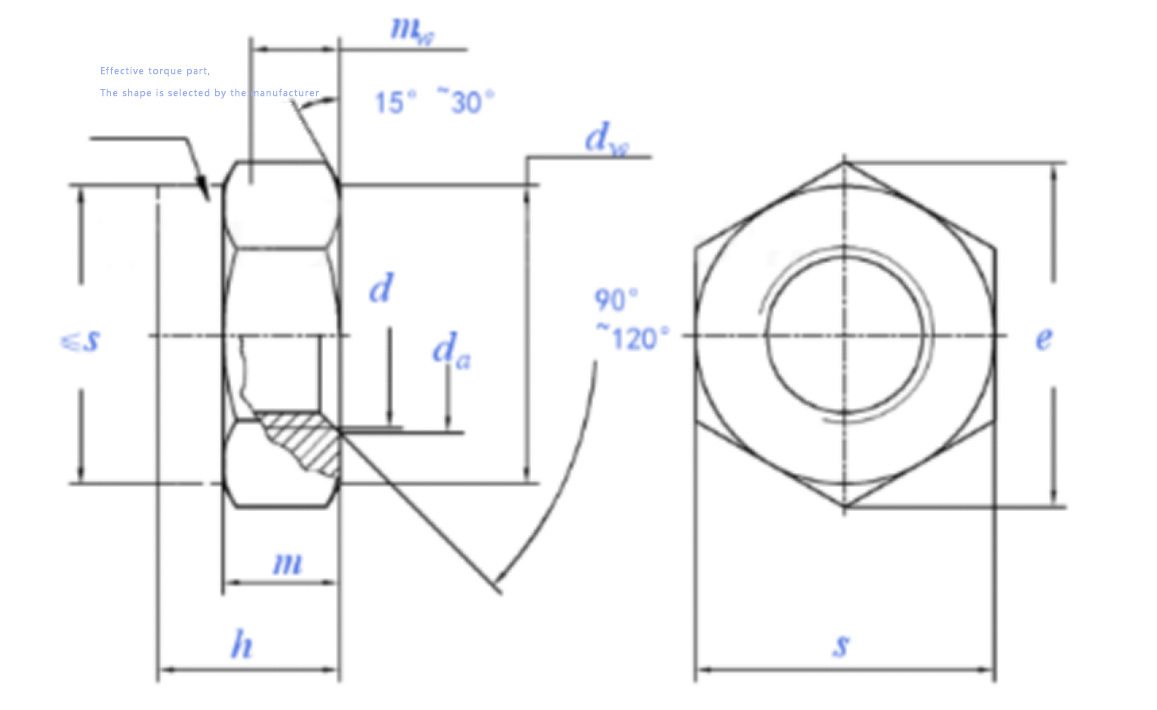

Non-metallic insert thin lock nut DIN 985 - 1987

Unit of measurement: mm

Thread size

dM3

M4

M5

M6

M7

M8

M10

M12

M14

M16

M18

P

Pitch Thick teeth 0.5

0.7

0.8

1

1

1.25

1.5

1.75

2

2

2.5

Fine teeth 1

/

/

/

/

/

1

1

1.5

1.5

1.5

2

Fine teeth 2

/

/

/

/

/

/

1.25

1.25

/

/

1.5

da

Min 3

4

5

6

7

8

10

12

14

16

18

Max 3.45

4.6

5.75

6.75

7.75

8.75

10.8

13

15.1

17.3

19.5

dw

Min

4.6

5.9

6.9

8.9

9.6

11.6

15.6

17.4

20.5

22.5

24.9

e

Min 6.01

7.66

8.79

11.05

12.12

14.38

18.9

21.1

24.49

26.75

29.56

h

Maximum value = nominal 4

5

5

6

7.5

8

10

12

14

16

18.5

Min 3.7

4.7

4.7

5.7

7.14

7.64

9.64

11.57

13.3

15.3

17.66

m

Min 2.4

2.9

3.2

4

4.7

5.5

6.5

8

9.5

10.5

13

mw

Min 1.65

2.2

2.75

3.3

3.85

4.4

5.5

6.6

7.7

8.8

9.9

s

Maximum value = nominal 5.5

7

8

10

11

13

17

19

22

24

27

Min 5.32

6.78

7.78

9.78

10.73

12.73

16.73

18.67

21.67

23.67

26.16

Thousand pieces weight kg

0.5

1

1.4

2.4

3

5.1

10.6

17.2

26

34

45

Thread size

dM20

M22

M24

M27

M30

M33

M36

M39

M42

M45

M48

P

Pitch Thick teeth 2.5

2.5

3

3

3.5

3.5

4

4

4.5

4.5

5

Fine teeth 1

2

2

2

2

2

2

3

3

3

3

3

Fine teeth 2

1.5

1.5

/

/

/

/

/

/

/

/

/

da

Min 20

22

24

27

30

33

36

39

42

45

48

Max

21.6

23.7

25.9

29.1

32.4

35.6

38.9

42.1

45.4

48.6

51.8

dw

Min 27.7

29.5

33.2

38

42.7

46.6

51.1

55.9

60.6

64.7

69.4

e

Min 32.95

35.03

39.55

45.2

50.85

55.37

60.79

66.44

72.09

76.95

82.6

h

Maximum value = nominal 20

22

24

27

30

33

36

39

42

45

48

Min 18.7

20.7

22.7

25.7

28.7

31.4

34.4

37.4

40.4

43.4

46.4

m

Min 14

15

15

17

19

22

25

27

29

32

36

mw

Min 11

12.2

13.2

14.8

16.5

18.2

19.8

21.5

23.1

24.8

26.5

s

Maximum value = nominal 30

32

36

41

46

50

55

60

65

70

75

Min 29.16

31

35

40

45

49

53.8

58.8

63.8

68.1

73.1

Thousand pieces weight kg

65

75

100

162

212

317

415

499

628

771

998

Nylon lock nut is a commonly used fastener, mainly used in occasions where high strength and anti-loosening are required.Because of its excellent vibration resistance, corrosion resistance and high temperature resistance, it is widely used in automotive, aviation, chemical industry, electric power and other fields.The main feature of nylon lock nuts is that they can be automatically locked during work, effectively prevent the screws from loosening, and improve the reliability and safety of the equipment.

Working principle

The working principle of nylon lock nuts mainly depends on the characteristics of nylon material.When the screw is screwed into the nut, the nylon material will be stretched, resulting in elastic deformation.During the unscrewing process, due to the memory effect of nylon material, the nut will return to its original shape, resulting in a reverse torque, resulting in a tighter clamping force between the screw and the nut.This reverse torque can prevent the screws from loosening, thereby ensuring the stability and reliability of the equipment.

Advantages

1. Automatic locking: Nylon lock nuts can be automatically locked during work, effectively preventing the screws from loosening and improving the reliability and safety of the equipment.

2. Corrosion resistance: Nylon lock nuts are made of nylon material, which has good corrosion resistance and can adapt to various harsh environments.

3. High temperature resistance: Nylon lock nuts can maintain excellent performance in high temperature environments and are suitable for various high temperature equipment.

4. Good vibration resistance: Due to the elasticity of nylon material, nylon lock nuts can absorb vibration and reduce the impact of equipment vibration on screws.

5. Long service life: The long service life of nylon lock nuts can ensure the long-term stable operation of the equipment.

Application scenario

1. Automobile industry: Nylon lock nuts are widely used in automobile engines, chassis, suspension systems and other parts to improve the safety and reliability of automobiles.

2. Aviation industry: In aircraft manufacturing, due to the extremely high requirements for safety and reliability, nylon lock nuts are widely used in the fastening of aircraft structural parts.

Support customized precision machining

Drawings, samples and materials can be customized on demand

Ensure product accuracy

Fast proofing

Fast delivery

Come and customize your exclusive products

Customization process

Consult customer service

01

Determine the demand

02

Provide spot samples

03

Provide quotation

04

Sign a contract and pay a deposit

05

Proofing is determined

06

Pay and ship as agreed

07

After-sales service

08

Mode of transportation

Sales area

Get A Quote

undefined

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products