Contact Us

Add:15-11, West District, China International Standard Parts Industrial City, Handan City, Hebei Province, China

Tel:+86-18634133666 +86-15284383180

E-mial:cindy@hdwxfasteners.com

WhatsApp: +86-15284383180

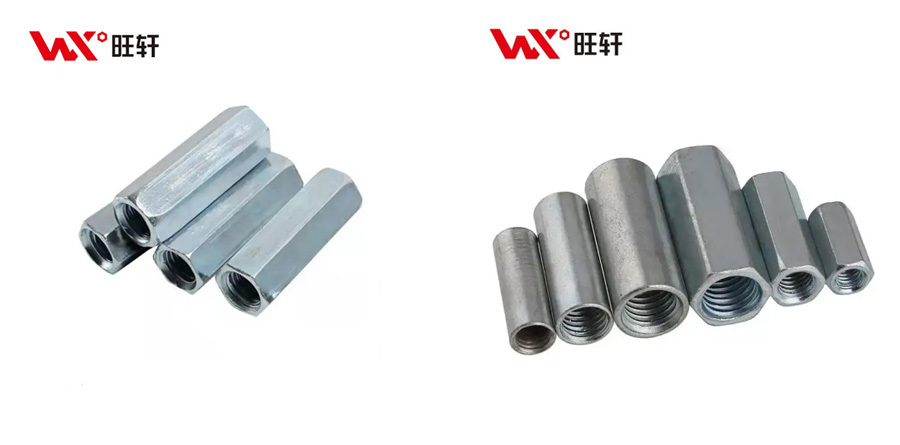

Galvanized Cylindrical Long Hex/Round Coupling Nuts

- Commodity name: Galvanized Cylindrical Long Hex/Round Coupling Nuts

- DESCRIPTION

-

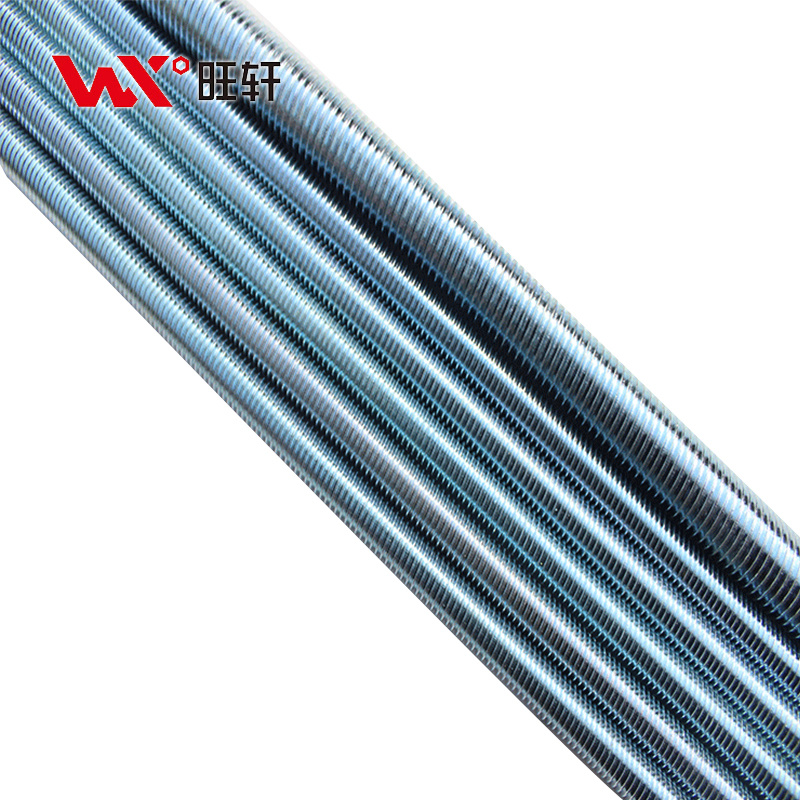

Round coupling long nut / Hex coupling long nut

Name

Round coupling long nut / Hex coupling long nut Material

Carbon steel/stainless steel Grade 4.8 /6.8 /8.8 /10.9/ 12.9

Color White zinc/blue and white zinc/black/yellow zinc/natural color

Model number M6-M30/1/4"-1"

Type Hexagonal/round

Packaging Bag put tray /box put tray /can be customized

Long nuts are divided into hexagonal long nuts and round long nuts

1. Hexagonal long nuts and round long nuts are common fasteners used to connect various equipment, parts or structures together.

2. Application of hexagonal long nut

Hexagonal long nuts have good carrying capacity and high stability, so they are widely used in situations where they need to withstand large loads.For example, in the fields of construction, bridges, chemical industry, electric power, etc., hexagonal long nuts are often used to fix equipment, pipelines, and brackets.At the same time, due to its hexagonal design, it can be used in environments with limited space and is easy to install and disassemble.

3. the application of round long nuts

Round long nuts usually have good self-locking performance, and are suitable for equipment with large vibration and occasions that require repeated disassembly and assembly.For example, in the fields of automobiles, ships, and aviation, round long nuts are often used to fix engines, transmission systems, and seats.In addition, when sealing is required, round long nuts can also play a certain sealing role.

Hexagonal long nuts and round long nuts are common fasteners and have a wide range of applications.When choosing and using, it should be selected according to the specific working environment and needs, and the correct method of use should be followed.Through reasonable application, the stability and reliability of the equipment can be effectively improved.

Support customized precision machining

Drawings, samples and materials can be customized on demand

Ensure product accuracy

Fast proofing

Fast delivery

Come and customize your exclusive products

Customization process

Consult customer service

01

Determine the demand

02

Provide spot samples

03

Provide quotation

04

Sign a contract and pay a deposit

05

Proofing is determined

06

Pay and ship as agreed

07

After-sales service

08

Mode of transportation

Sales area

Get A Quote

undefined

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!