Contact Us

Add:15-11, West District, China International Standard Parts Industrial City, Handan City, Hebei Province, China

Tel:+86-18634133666 +86-15284383180

E-mial:cindy@hdwxfasteners.com

WhatsApp: +86-15284383180

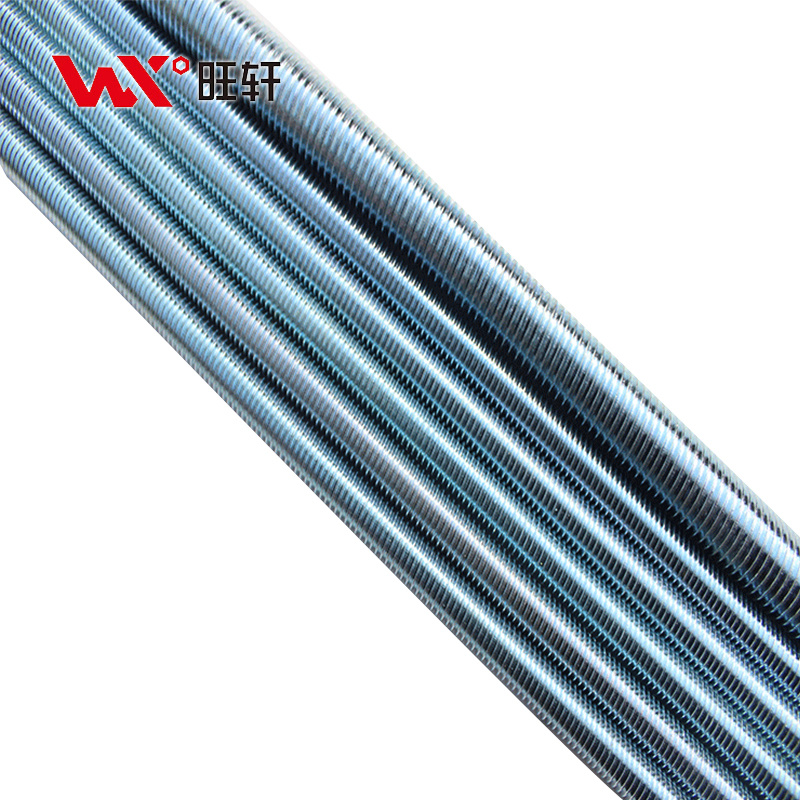

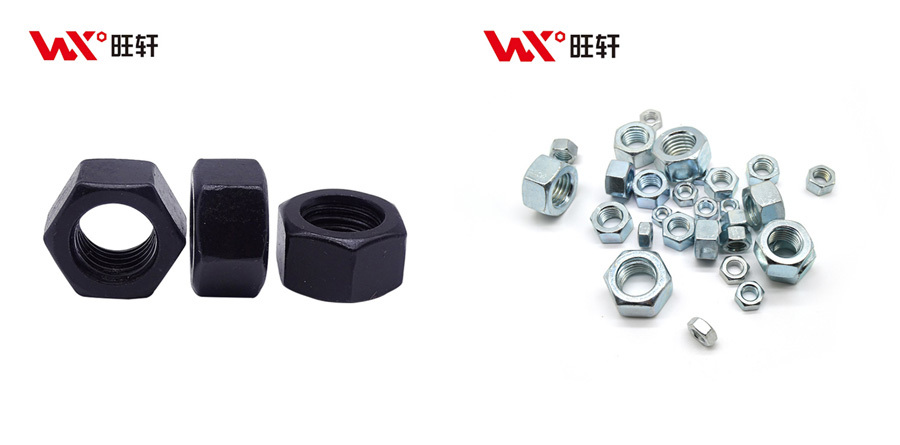

Custom Zinc Plated Finish HDG Thread Hex Nuts

- Commodity name: Custom Zinc Plated Finish HDG Thread Hex Nuts

- DESCRIPTION

-

Hex nut

Name Hex nut Material Carbon steel/stainless steel Grade 4.8 /6.8 /8.8 /10.9/ 12.9

Color White zinc/blue and white zinc/black/yellow zinc/natural color Model number M6-M64/1/4"-2"

Packaging Bag put tray /box put tray /can be customized

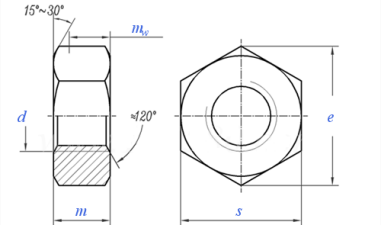

Hexagon nut metric coarse and fine thread class A and Class B DIN 934-1987

Unit of measurement: mm

3D drawing

Weight calculation

Calculation of arithmetic progress difference

Correct the errorThread size

dM1

M1.2

M1.4

M1.6

(M1.7)

M2

(M2.3)

M2.5

(M2.6)

M3

(M3.5)

M4

M5

M6

(M7)

M8

P

Pitch Thick teeth 0.25

0.25

0.3

0.35

0.35

0.4

0.45

0.45

0.45

0.5

0.6

0.7

0.8

1

1

1.25

Fine teeth 1

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

1

Fine teeth 2

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

m

Max=Nominal

0.8

1

1.2

1.3

1.4

1.6

1.8

2

2

2.4

2.8

3.2

4

5

5.5

6.5

Min 0.55

0.75

0.95

1.05

1.15

1.35

1.55

1.75

1.75

2.15

2.55

2.9

3.7

4.7

5.2

6.14

mw

Min

0.44

0.6

0.76

0.84

0.92

1.08

1.24

1.4

1.4

1.72

2.04

2.32

2.96

3.76

4.16

4.91

s

Max=Nominal

2.5

3

3

3.2

3.5

4

4.5

5

5

5.5

6

7

8

10

11

13

Min 2.4

2.9

2.9

3.02

3.38

3.82

4.32

4.82

4.82

5.32

5.82

6.78

7.78

9.78

10.73

12.73

e ①

Min 2.71

3.28

3.28

3.41

3.82

4.32

4.88

5.45

5.45

6.01

6.58

7.66

8.79

11.05

12.12

14.38

*

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Thousand pieces of weight (steel)≈kg

0.03

0.054

0.063

0.076

0.1

0.142

0.2

0.28

0.72

0.384

0.514

0.81

1.23

2.5

3.12

5.2

Thread size

dM10

M12

(M14)

M16

(M18)

M20

(M22)

M24

(M27)

M30

(M33)

M36

(M39)

M42

(M45)

M48

P

Pitch Thick teeth 1.5

1.75

2

2

2.5

2.5

2.5

3

3

3.5

3.5

4

4

4.5

4.5

5

Fine teeth 1

1

1.5

1.5

1.5

1.5

2

1.5

2

2

2

2

3

3

3

3

3

Fine teeth 2

1.25

1.25

/

/

2

1.5

2

/

/

/

/

/

/

/

/

/

m

Max=Nominal

8

10

11

13

15

16

18

19

22

24

26

29

31

34

36

38

Min 7.64

9.64

10.3

12.3

14.3

14.9

16.9

17.7

20.7

22.7

24.7

27.4

29.4

32.4

34.4

36.4

mw

Min 6.11

7.71

8.24

9.84

11.44

11.92

13.52

14.16

16.56

18.16

19.76

21.92

23.52

25.9

27.5

29.1

s

Max=Nominal

17

19

22

24

27

30

32

36

41

46

50

55

60

65

70

75

Min 16.73

18.67

21.67

23.67

26.16

29.16

31

35

40

45

49

53.8

58.8

63.1

68.1

73.1

e ①

Min 18.9

21.1

24.49

26.75

29.56

32.95

35.03

39.55

45.2

50.85

55.37

60.79

66.44

71.3

76.95

82.6

*

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Thousand pieces of weight (steel)≈kg

11.6

17.3

25

33.3

49.4

64.4

79

110

165

223

288

393

502

652

800

977

Thread size

d(M52)

M56

(M60)

M64

(M68)

M72

(M76)

M80

(M85)

M90

M100

M110

M125

M140

M160

P

Pitch Thick teeth 5

5.5

5.5

6

6

/

/

/

/

/

/

/

/

/

/

Fine teeth 1

3

4

4

4

/

6

6

6

6

6

6

6

6

6

6

Fine teeth 2

/

/

/

/

4

4

4

4

4

4

4

4

4

/

/

m

Max=Nominal

42

45

48

51

54

58

61

64

68

72

80

88

100

112

128

Min 40.4

43.4

46.4

49.1

52.1

56.1

59.1

62.1

66.1

70.1

78.1

85.8

97.8

109.8

125.5

mw

Min 32.3

34.7

37.1

39.3

41.7

44.9

47.3

49.7

52.9

56.1

62.5

68.6

78.2

87.8

100

s

Max=Nominal

80

85

90

95

100

105

110

115

120

130

145

155

180

200

230

Min 78.1

82.8

87.8

92.8

97.8

102.8

107.8

112.8

117.8

127.5

142.5

152.5

177.5

195.4

225.4

e ①

Min 88.25

93.56

99.21

104.86

110.51

116.16

121.81

127.46

133.11

144.08

161.02

172.32

200.57

220.8

254.7

*

-

-

-

-

-

-

-

-

-

-

-

170

196

216

248

Thousand pieces of weight (steel)≈kg

1220

1420

1690

1980

2300

2670

3040

3440

3930

4930

6820

8200

13000

17500

26500

Classification of hexagon nuts

Hexagonal nuts are one of the most widely used nut types. Their shape is hexagonal and they are usually used in conjunction with bolts.According to different classification methods, there are many types of hexagonal nuts. Some common classifications are listed below.

1. Depending on the manufacturing materials, hexagonal nuts can be divided into iron nuts and stainless steel nuts. Iron nuts are made of carbon steel and other materials, while stainless steel screws are usually made of stainless steel materials such as 304 or 316.

2. According to the different thread specifications, hexagonal nuts can be divided into metric and imperial. Metric threads are in millimeters and imperial threads are in inches.

The use of hexagon nuts

As a commonly used fastener, hexagon nut is widely used in various manufacturing fields such as machinery, equipment, and vehicles.Specific uses include but are not limited to the following aspects:

1. Fixing effect: The bolts are fixed to the workpiece, so as to firmly connect other components or components together to achieve the stability of the mechanical structure.

2. Connection function: Connect two or more components or components together to form a complete system or device.

3. Adjustment effect: By adjusting the tightness of bolts and hexagonal nuts, parameters such as the size, position or angle of machinery and equipment can be adjusted to meet specific requirements.

About Us

Handan Wangxuan Fastener Manufacturing Co., Ltd. is located in Standard Parts Industrial Zone, Yongnian District, Handan City, Hebei Province, China, Is a self-produced and self-sold enterprises, the company has first-class production equipment, professional technical team and sales team, adhere to customer demand as the basis, to provide customers with high-quality products at the same time, and strive to do everything for customers!

We export studs, bolts, nuts, washers, sleeve anchors and pins. We have been in the market for many years, with professional standards. Believe you have been looking for ways to reduce costs. If you have any fastener requirements, we must give you a competitive quotation.

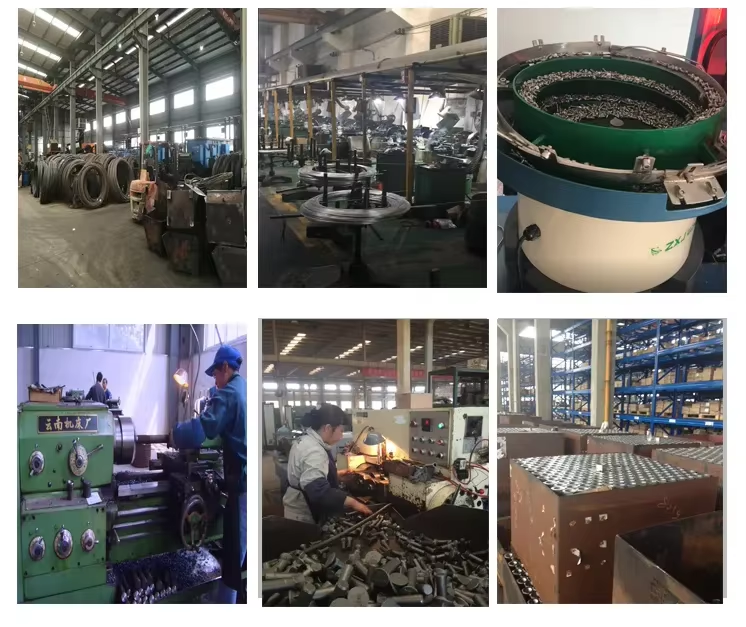

Workshop

QC and Warehouse

Our quality inspection staff uses a variety of inspection methods to strictly inspect raw materials, semi-finished products and finished products, find quality problems in time, and urge improvement to ensure that products meet the quality requirements of customers.

Our warehouse covers a vast area and has many shelves. In the warehouse, from screws and nuts to mechanical accessories, different specifications of hardware products are accurately collected, showing the scale and order.

Advantages

★ High quality and most competitive price;

★ Advanced produce and inspecting equipment;

★ Customized design is available. ODM&OEM are welcomed;

★ We can provide free sample, consumer should pay the freight first;

★ Good after-sale service, all questions will be replied within 12 hours;

★ Convenient transportation and fast delivery, all available shipping ways could be applied, by express, air or sea.

Shipping

FAQ

Q1: What can you buy from us?

A1: Hex bolts, hex nuts, flat washers, threaded rods, double head threaded rods and self drilling screw.

Q2: When can I get the price?

A2: We usually offer you a quotation within 12 hours, and the special offer is not more than 24 hours.Any urgent cases, please contact us directly by phone or send email to us.

Q3: The quality of your products?

A3: The company has advanced production and testing equipment .Every products will be 100% inspected by our qc department before shipment.

Q4: Can I get discounts?

A4: Yes, for big order, frequent customers, we give reasonable discounts.

Q5: Could you provide free samples?

A5: We can provide free samples for standard fastener, But the clients will pay the Express charges.

Q6: What’s your Delivery Time?

A6:Standard parts: 5-7days,Non-standard parts: 15-25days.We will make the delivery as soon as possible with the guarantee quality.

Consult customer service

01

Determine the demand

02

Provide spot samples

03

Provide quotation

04

Sign a contract and pay a deposit

05

Proofing is determined

06

Pay and ship as agreed

07

After-sales service

08

Mode of transportation

Sales area

Get A Quote

undefined

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!