Products Center

Contact Us

Add:15-11, West District, China International Standard Parts Industrial City, Handan City, Hebei Province, China

Tel:+86-18634133666 +86-15284383180

E-mial:cindy@hdwxfasteners.com

WhatsApp: +86-15284383180

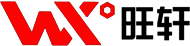

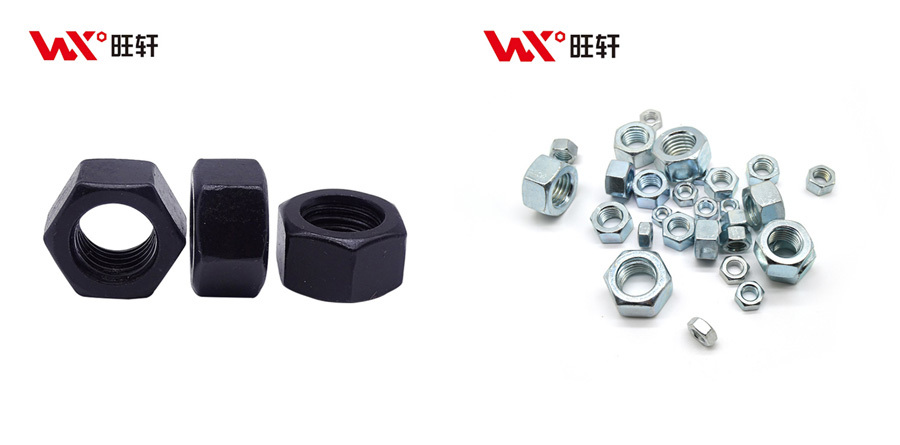

Custom Wholesale Carbon Steel UNC Black Hex Nut

- Commodity name: Custom Wholesale Carbon Steel UNC Black Hex Nut

- DESCRIPTION

-

Hex nut

Name Hex nut Material Carbon steel/stainless steel Grade 4.8 /6.8 /8.8 /10.9/ 12.9

Color White zinc/blue and white zinc/black/yellow zinc/natural color Model number M6-M64/1/4"-2"

Packaging Bag put tray /box put tray /can be customized

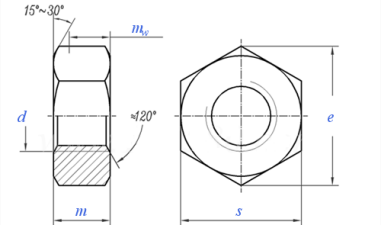

Hexagon nut metric coarse and fine thread class A and Class B DIN 934-1987

Unit of measurement: mm

3D drawing

Weight calculation

Calculation of arithmetic progress difference

Correct the errorThread size

dM1

M1.2

M1.4

M1.6

(M1.7)

M2

(M2.3)

M2.5

(M2.6)

M3

(M3.5)

M4

M5

M6

(M7)

M8

P

Pitch Thick teeth 0.25

0.25

0.3

0.35

0.35

0.4

0.45

0.45

0.45

0.5

0.6

0.7

0.8

1

1

1.25

Fine teeth 1

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

1

Fine teeth 2

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

m

Max=Nominal

0.8

1

1.2

1.3

1.4

1.6

1.8

2

2

2.4

2.8

3.2

4

5

5.5

6.5

Min 0.55

0.75

0.95

1.05

1.15

1.35

1.55

1.75

1.75

2.15

2.55

2.9

3.7

4.7

5.2

6.14

mw

Min

0.44

0.6

0.76

0.84

0.92

1.08

1.24

1.4

1.4

1.72

2.04

2.32

2.96

3.76

4.16

4.91

s

Max=Nominal

2.5

3

3

3.2

3.5

4

4.5

5

5

5.5

6

7

8

10

11

13

Min 2.4

2.9

2.9

3.02

3.38

3.82

4.32

4.82

4.82

5.32

5.82

6.78

7.78

9.78

10.73

12.73

e ①

Min 2.71

3.28

3.28

3.41

3.82

4.32

4.88

5.45

5.45

6.01

6.58

7.66

8.79

11.05

12.12

14.38

*

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Thousand pieces of weight (steel)≈kg

0.03

0.054

0.063

0.076

0.1

0.142

0.2

0.28

0.72

0.384

0.514

0.81

1.23

2.5

3.12

5.2

Thread size

dM10

M12

(M14)

M16

(M18)

M20

(M22)

M24

(M27)

M30

(M33)

M36

(M39)

M42

(M45)

M48

P

Pitch Thick teeth 1.5

1.75

2

2

2.5

2.5

2.5

3

3

3.5

3.5

4

4

4.5

4.5

5

Fine teeth 1

1

1.5

1.5

1.5

1.5

2

1.5

2

2

2

2

3

3

3

3

3

Fine teeth 2

1.25

1.25

/

/

2

1.5

2

/

/

/

/

/

/

/

/

/

m

Max=Nominal

8

10

11

13

15

16

18

19

22

24

26

29

31

34

36

38

Min 7.64

9.64

10.3

12.3

14.3

14.9

16.9

17.7

20.7

22.7

24.7

27.4

29.4

32.4

34.4

36.4

mw

Min 6.11

7.71

8.24

9.84

11.44

11.92

13.52

14.16

16.56

18.16

19.76

21.92

23.52

25.9

27.5

29.1

s

Max=Nominal

17

19

22

24

27

30

32

36

41

46

50

55

60

65

70

75

Min 16.73

18.67

21.67

23.67

26.16

29.16

31

35

40

45

49

53.8

58.8

63.1

68.1

73.1

e ①

Min 18.9

21.1

24.49

26.75

29.56

32.95

35.03

39.55

45.2

50.85

55.37

60.79

66.44

71.3

76.95

82.6

*

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Thousand pieces of weight (steel)≈kg

11.6

17.3

25

33.3

49.4

64.4

79

110

165

223

288

393

502

652

800

977

Thread size

d(M52)

M56

(M60)

M64

(M68)

M72

(M76)

M80

(M85)

M90

M100

M110

M125

M140

M160

P

Pitch Thick teeth 5

5.5

5.5

6

6

/

/

/

/

/

/

/

/

/

/

Fine teeth 1

3

4

4

4

/

6

6

6

6

6

6

6

6

6

6

Fine teeth 2

/

/

/

/

4

4

4

4

4

4

4

4

4

/

/

m

Max=Nominal

42

45

48

51

54

58

61

64

68

72

80

88

100

112

128

Min 40.4

43.4

46.4

49.1

52.1

56.1

59.1

62.1

66.1

70.1

78.1

85.8

97.8

109.8

125.5

mw

Min 32.3

34.7

37.1

39.3

41.7

44.9

47.3

49.7

52.9

56.1

62.5

68.6

78.2

87.8

100

s

Max=Nominal

80

85

90

95

100

105

110

115

120

130

145

155

180

200

230

Min 78.1

82.8

87.8

92.8

97.8

102.8

107.8

112.8

117.8

127.5

142.5

152.5

177.5

195.4

225.4

e ①

Min 88.25

93.56

99.21

104.86

110.51

116.16

121.81

127.46

133.11

144.08

161.02

172.32

200.57

220.8

254.7

*

-

-

-

-

-

-

-

-

-

-

-

170

196

216

248

Thousand pieces of weight (steel)≈kg

1220

1420

1690

1980

2300

2670

3040

3440

3930

4930

6820

8200

13000

17500

26500

Classification of hexagon nuts

Hexagonal nuts are one of the most widely used nut types. Their shape is hexagonal and they are usually used in conjunction with bolts.According to different classification methods, there are many types of hexagonal nuts. Some common classifications are listed below.

1. Depending on the manufacturing materials, hexagonal nuts can be divided into iron nuts and stainless steel nuts. Iron nuts are made of carbon steel and other materials, while stainless steel screws are usually made of stainless steel materials such as 304 or 316.

2. According to the different thread specifications, hexagonal nuts can be divided into metric and imperial. Metric threads are in millimeters and imperial threads are in inches.

The use of hexagon nuts

As a commonly used fastener, hexagon nut is widely used in various manufacturing fields such as machinery, equipment, and vehicles.Specific uses include but are not limited to the following aspects:

1. Fixing effect: The bolts are fixed to the workpiece, so as to firmly connect other components or components together to achieve the stability of the mechanical structure.

2. Connection function: Connect two or more components or components together to form a complete system or device.

3. Adjustment effect: By adjusting the tightness of bolts and hexagonal nuts, parameters such as the size, position or angle of machinery and equipment can be adjusted to meet specific requirements.

Support customized precision machining

Drawings, samples and materials can be customized on demand

Ensure product accuracy

Fast proofing

Fast delivery

Come and customize your exclusive products

Customization process

Consult customer service

01

Determine the demand

02

Provide spot samples

03

Provide quotation

04

Sign a contract and pay a deposit

05

Proofing is determined

06

Pay and ship as agreed

07

After-sales service

08

Mode of transportation

Sales area

Get A Quote

undefined

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products